1.FKM(Viton)O-Ring Performance Specifications

FKM is a family of fluorocarbon-based fluoroelastomer materials defined by the ASTM D1418 standard.Fluorocarbon(FKM)has excellent resistance to high temperatures,ozone, oxygen,mineral oil,synthetic hydraulic fluids,fuels,aromatics and many organic solvents and chemicals.Viton®o-ring's temperature resistance range is one of its most notable attributes,with the capability to endure extremes from-15°F(-26℃)to+400 F(+205℃),and even higher for shorter periods.Standard FKM O-ring temperature ranges are from-15°F to 40O°F.Depending on the grade the working temperature range is considered to be-26℃ to+205°/230℃(-15°F to +400°/440°F).Fluorocarbon elastomers have grown to major importance in the sealing industry due to its wide range of chemical compatibility,temperature range,low compression set,and excellent aging characteristics. These fkm o ring components provide outstanding performance over a broad thermal range and excellent resistance to aging and ozone.FKM offers superior resistance to oils,fuels, and a wide range of chemicals,making them ideal for demanding sealing applications.

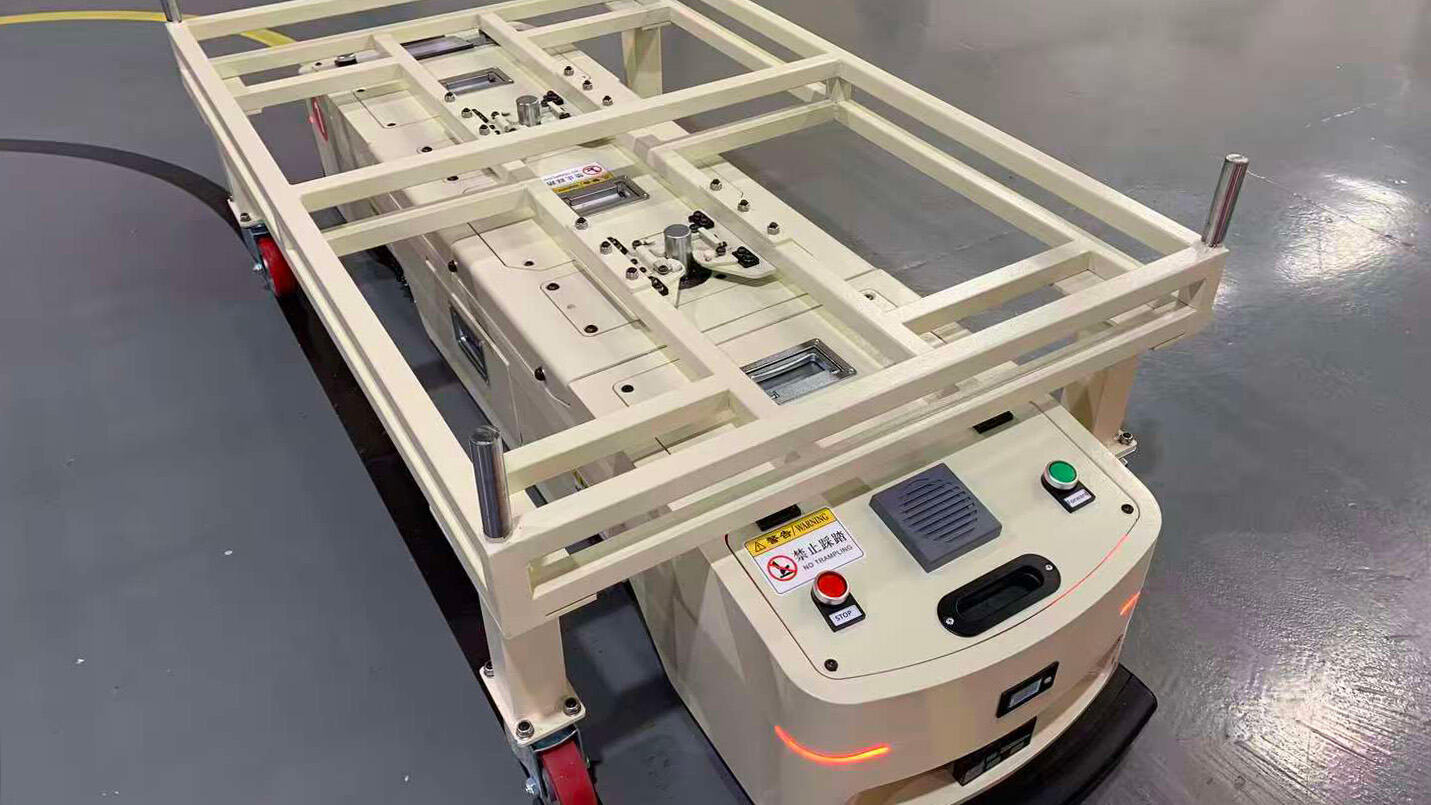

2.Industrial Robots,Manipulators,and AGV Working Conditions

In modern automation,industrial robots,manipulators,and automated guided vehicles (AGVs)rely on high-precision joints and actuators that often operate in continuous cycles where internal friction generates significant heat.In harsh environments such as chemical processing or high-temperature applications,FKM seals protect internal components from aggressive chemicals,fumes,and thermal stress.High-performance seals are essential for extending the life of robotic joints,actuators,and automated systems.In industrial robotics,seals and O-rings play a crucial role in ensuring smooth and reliable operation, preventing leaks and keeping contaminants out.Specialized sealing solutions enhance the efficiency and dependability of automated guided vehicles.FKM O-rings are frequently used in pneumatic systems,grippers,and housing seals to maintain airtight integrity and prevent leakage of specialized lubricants,which is critical for precision movements in robotic arms and mobile platforms.

3.AS-018 Size Chart &Dimensions for Robotics

The AS-018 is a common size for small-to-medium robotic components within the fkm o ring category.

|

AS568 Dash No. |

Inside Diameter (ID) |

Cross Section (CS) |

Material |

Hardness |

|

AS-017 |

0.676 in (17.17 mm) |

0.070 in (1.78 mm) |

FKM (Viton) |

75 Shore A |

|

AS-018 |

0.739 in (18.77 mm) |

0.070 in (1.78 mm) |

FKM (Viton) |

75 Shore A |

|

AS-019 |

0.801 in (20.35 mm) |

0.070 in (1.78 mm) |

FKM (Viton) |

75 Shore A |

Conclusion

When dealing with the high-duty cycles of industrial robotics,choosing the correct fkm o ring is vital to avoid thermal degradation and chemical attack.The AS-018 size provides a compact sealing solution for tight spaces in robotic joints.Always verify the fkm o-rings temperature range against your specific motor or actuator heat output to ensure peak performance and long-term reliability.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY