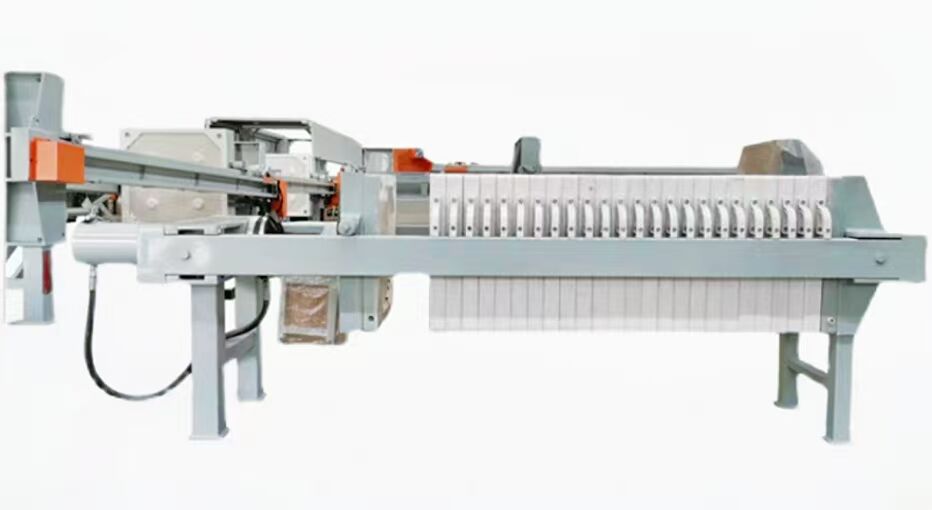

Filter presses and flotation machines are workhorses in mineral processing, wastewater treatment, and chemical manufacturing. They operate in cycles of high pressure and aggressive chemical exposure, making seal integrity paramount. Filter presses, used for solid-liquid separation, subject seals to slurries containing acids (e.g., sulfuric in copper leaching), alkalis (caustic soda in alumina processing), and oxidizing agents. Flotation cells, which separate minerals via air bubbles, use various frothers and collectors (often organic reagents like xanthates) in a turbulent, aerated environment.

Ethylene Propylene Diene Monomer (EPDM) is a non-polar elastomer renowned for its outstanding resistance to polar substances. It performs exceptionally well with hot water, steam (up to 150°C), alkalis, acids (including phosphoric and acetic), silicone oils and greases, and alcohol-based brake fluids. Its excellent ozone and weathering resistance make it ideal for outdoor installations. However, EPDM has very poor resistance to petroleum-based oils, greases, and fuels, severely limiting its use in general industrial lubrication systems.

Fluorocarbon (FKM) fills this gap. It is highly resistant to oils, fuels, aromatics, and many organic solvents, along with good acid resistance (though not as universal as EPDM for strong acids). It handles higher temperatures than EPDM. Therefore, the machine's design dictates the seal choice: EPDM for water/steam lines, acid wash sections, or areas exposed to polar chemicals; FKM for hydraulic systems, lubrication points, or sections involving hydrocarbon-based process fluids.

The AS324 standard provides precise dimensional tolerances for these seals, ensuring they fit perfectly into the gland grooves of plates, frames, and manifold connections. A common failure point is using the wrong material for a mixed-media environment. For example, a filter press in a Russian potash mine might use EPDM seals on its water flushing lines but require FKM seals on its hydraulic plate-shifting mechanism.

A systematic approach involves:

1. Fluid Analysis: Catalog every chemical the seal will contact, including cleaning agents.

2. Temperature and Pressure Mapping: Identify the most severe conditions.

3. Mechanical Assessment: Consider cycle frequency, plate movement, and potential for abrasive particle ingress.

4. Standardization: Use AS568/AS324 dash numbers for procurement efficiency.

Mining operations in India's coal belt and the USA's phosphate regions have implemented material specification sheets for every sealing point on their filter presses. This practice, combined with regular seal inspection during filter cloth changes, has reduced unplanned downtime by over 40%. In some cases, dual-material seals or custom-coating processes are explored for unique challenges where a single material is insufficient.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY