33-99No. Mufu E Rd. Gulou District, Nanjing, China [email protected] | [email protected]

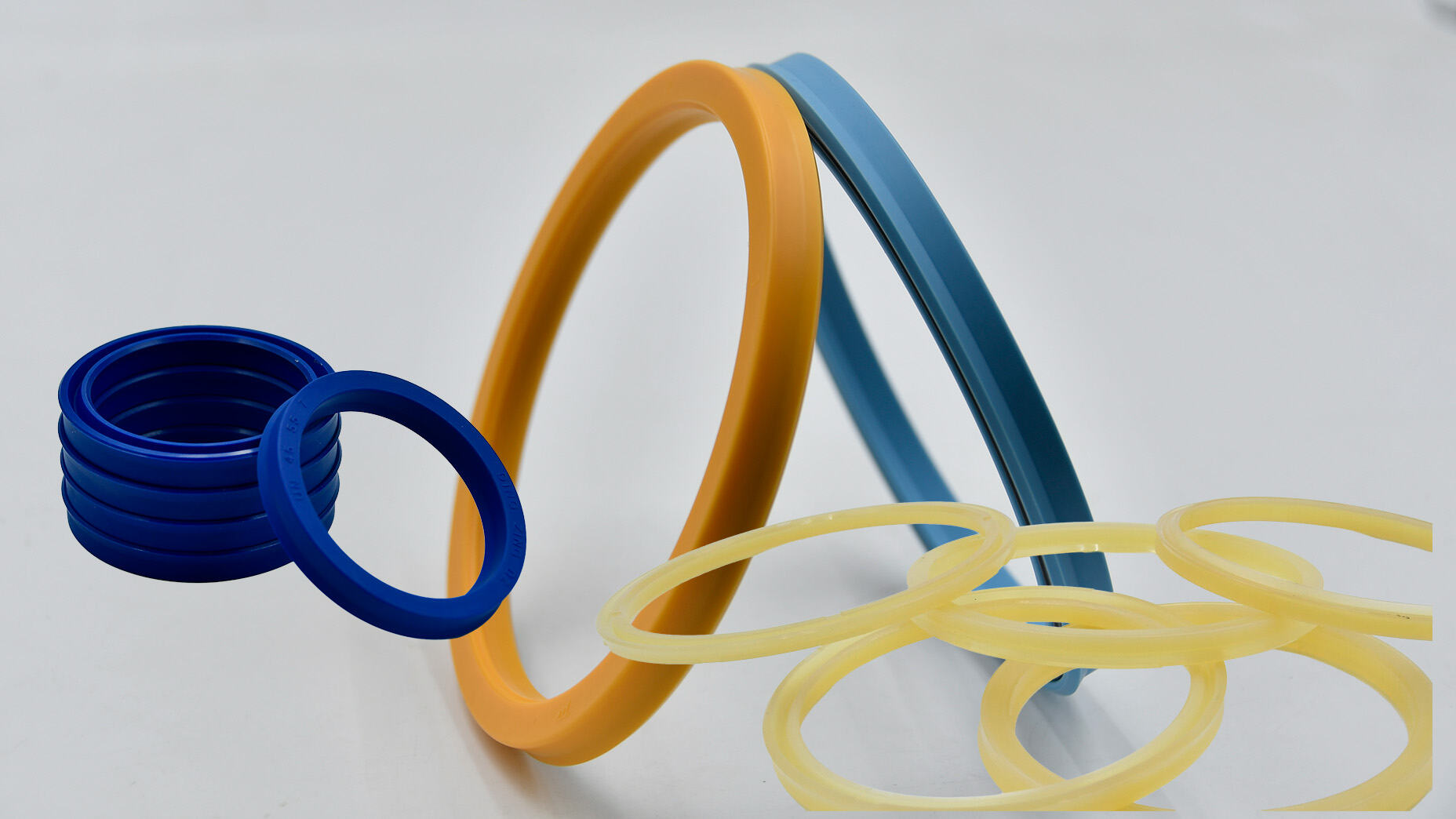

Amid the loud noise of a hydraulic breaker, with dust and debris flying all around, a simple sealing system quietly keeps this steel giant alive. Oil seals are ring-shaped parts. They work as hidden heroes. They separate the inside from the ou...

VIEW MORE

Different sealing points within the same machine impose completely different requirements on a U‑seal. Conversely, the identical U‑seal model can exhibit a hundred‑fold difference in service life when moved from one application to another. Multi‑work...

VIEW MORE

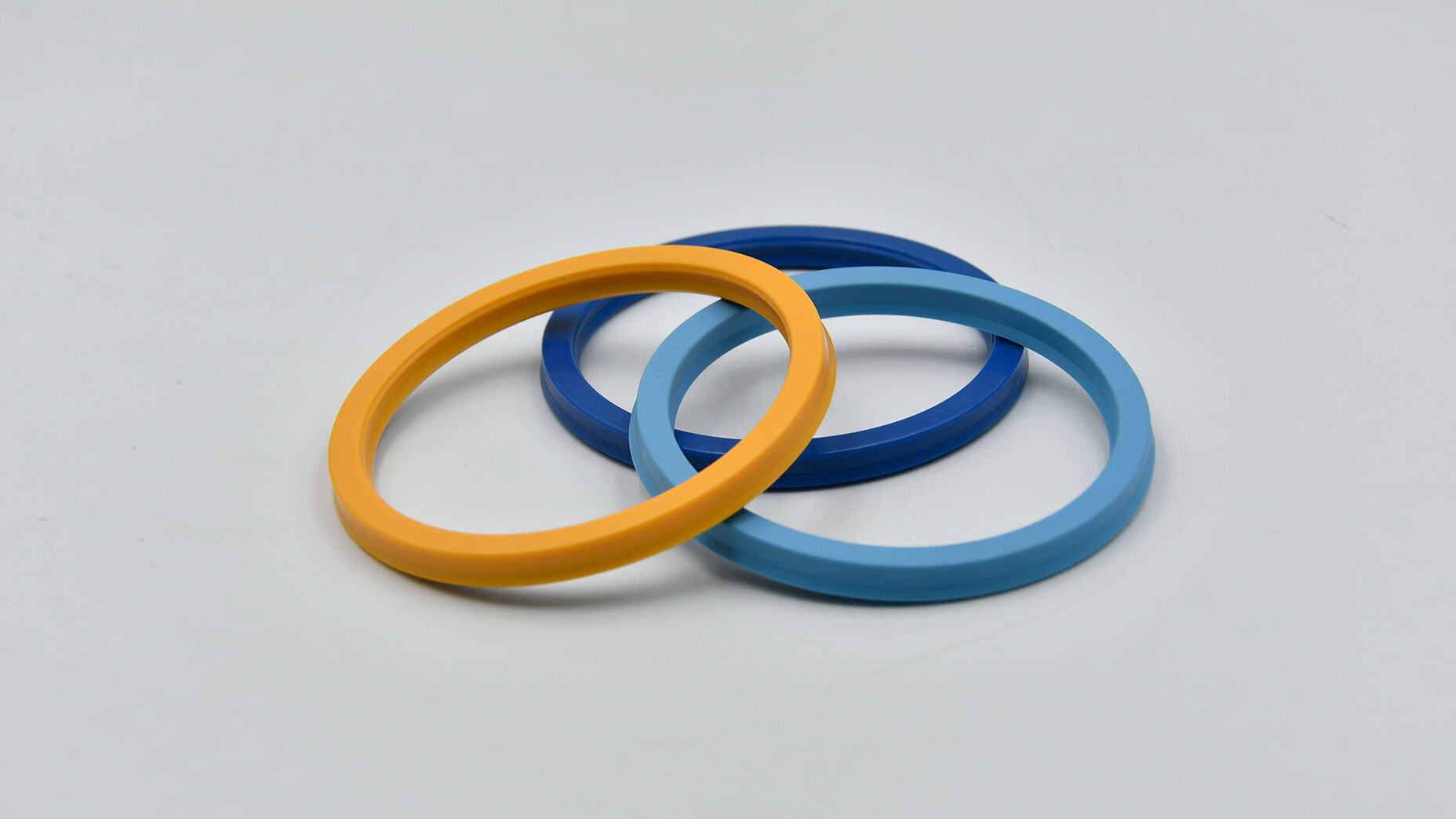

Engineers faced with the choice among NBR, FKM, and PU for a U‑seal application often ask: “Which one is best?” The truthful answer is: it depends. This article provides a three‑dimensional comparison—chemical, physical, economic&md...

VIEW MORE

The U‑seal, named for its characteristic U‑shaped cross‑section, is the most frequently used sealing element for hydraulic cylinder pistons and rods, and also serves as a low‑pressure buffer seal in pneumatics. This article is an encyclopedic knowled...

VIEW MORE

Eighty percent of hydraulic leakage failures originate from incorrect seal selection or improper installation. When U‑seals fail, the symptoms are often characteristic: chipped lips, root cracking, surface crazing, or uneven wear. This article review...

VIEW MORE

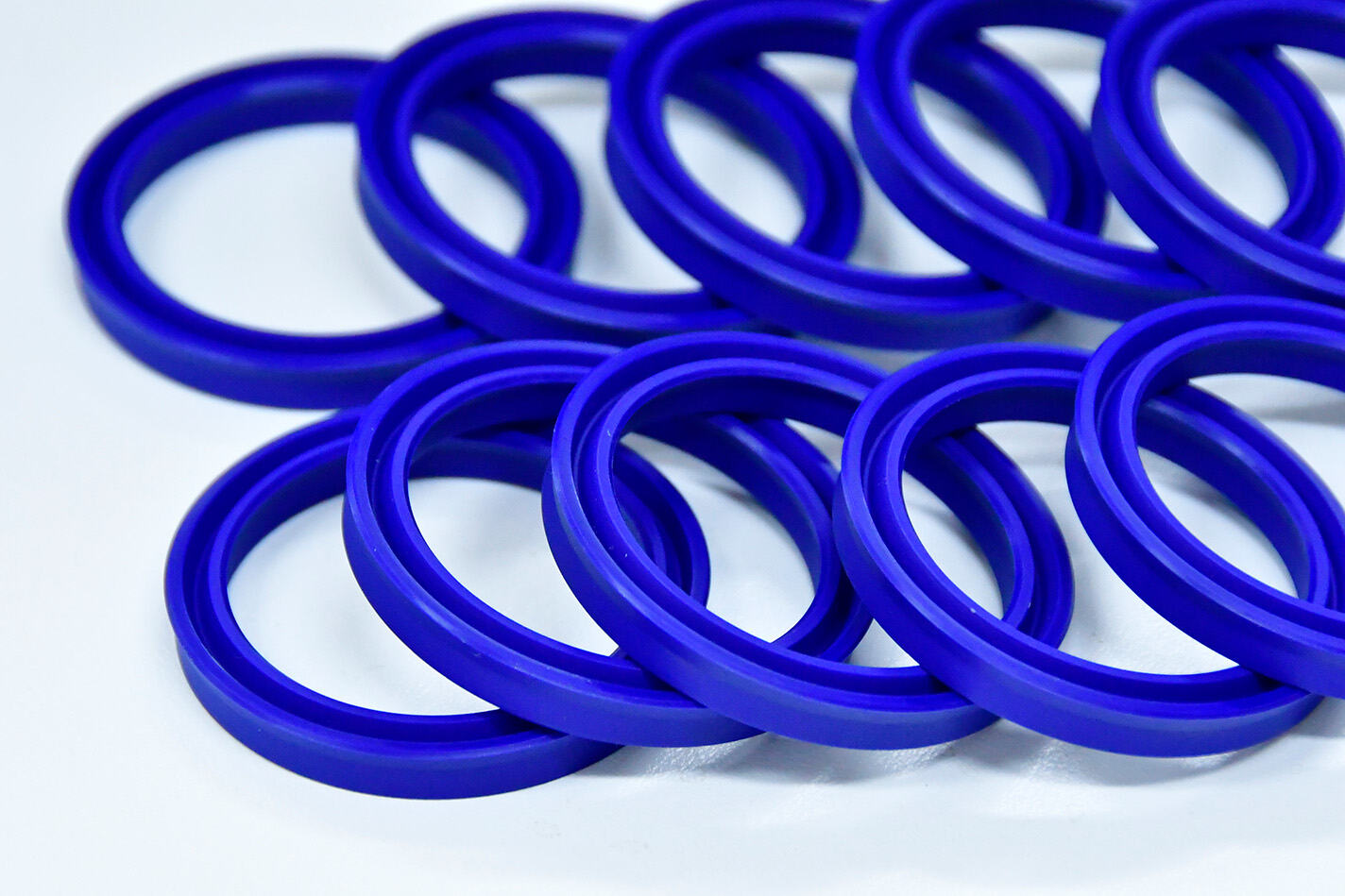

U‑seals are classified by their installation target as hole‑type (piston seal) or shaft‑type (rod seal). Although they look similar, their structure, pressure distribution, and failure modes are fundamentally different. Installing the wrong type&mdas...

VIEW MORE

Selecting the wrong U‑seal leads to leakage at best and catastrophic system failure at worst. Faced with dozens of material grades, cross‑section dimensions, and hardness values, engineers often fall back on “rules of thumb” or become pa...

VIEW MORE

“Cost‑effective” does not mean “cheap.” It means achieving the lowest total life‑cycle cost while meeting all functional requirements. For high‑volume, standardized hydraulic and pneumatic systems, the correct U‑seal selection...

VIEW MORE

U-seals are classified by installation mode as hole‑type (piston seal), shaft‑type (rod seal), or universal (groove‑compatible). In extreme environments characterized by high abrasion and elevated temperature, standard NBR can fail within hours. This...

VIEW MORE

In hydraulic and pneumatic systems, the U-seal is one of the most widely used and critical dynamic sealing components. Its unique U-shaped cross-section allows the lips to make controlled contact with the mating surface, achieving low-pressure activa...

VIEW MORE

SPGO Seal Overview SPGO is a low friction piston seal consisting of PTFE+Bronze seal ring and rubber o-ring used for two-way piston seal of Hydraulic cylinder.Spgo seal,also known as glyd ring,is a low friction piston seal,which improves the perfect ...

VIEW MORE

Seal Design and Structure PTFE Hydraulic Piston Rod Seal GSF Glyd Ring/Slide Ring/Step Seal Made in China.BSF Seal Bronze PTFE Compact Piston Rod Seal Glyd Ring SPGO Seal.The GSF profiles are double acting composite seals composed of a filled PTFE f...

VIEW MORE