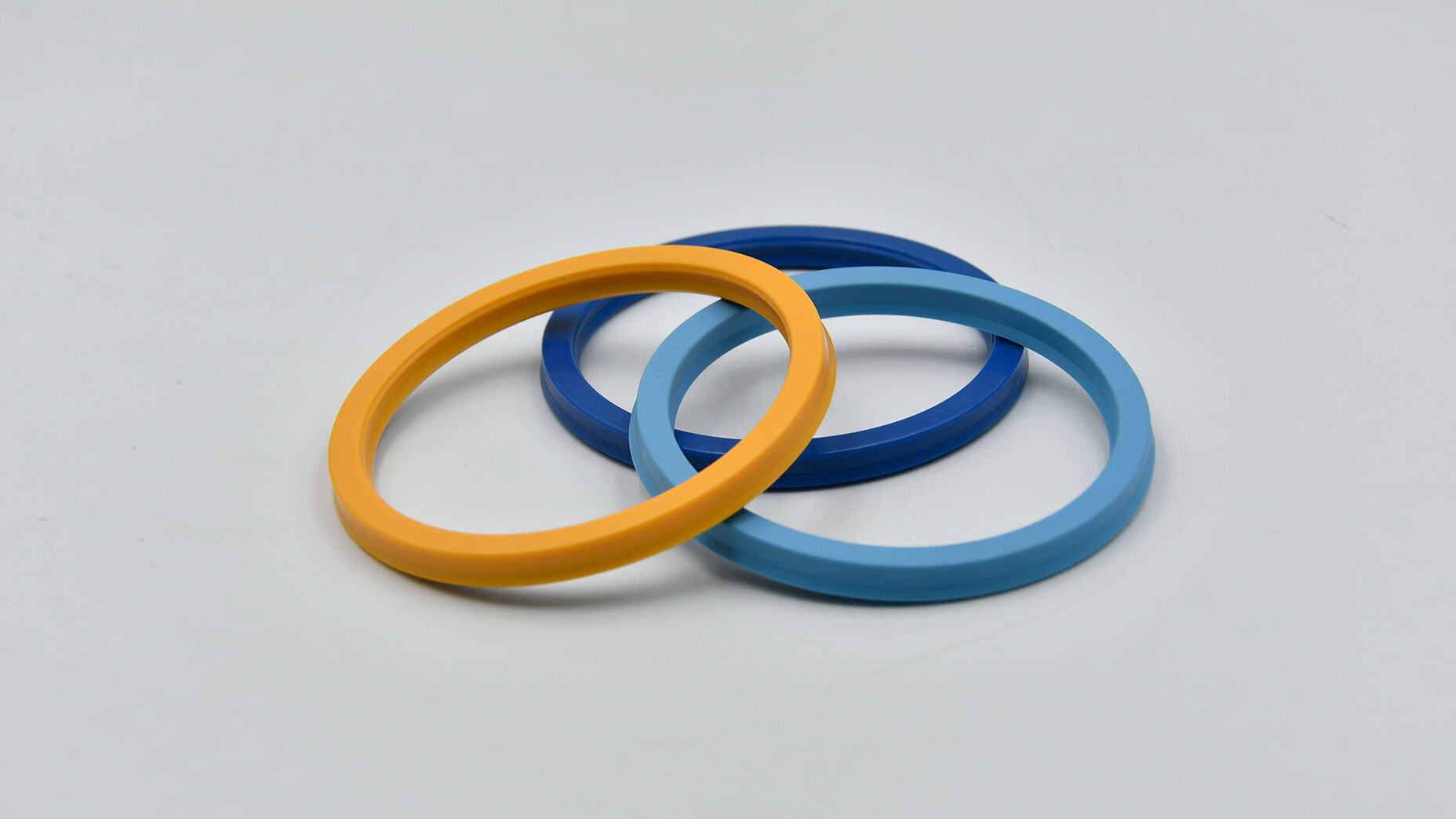

U-seals are classified by installation mode as hole‑type (piston seal), shaft‑type (rod seal), or universal (groove‑compatible). In extreme environments characterized by high abrasion and elevated temperature, standard NBR can fail within hours. This product series focuses on two core performance attributes—wear resistance and temperature resistance—and is offered in all three mounting configurations to provide a single‑source solution for demanding applications such as breaker hammers, die‑casting machines, and tunnel boring equipment.

1. Four Technology Pillars of Wear‑Resistant U‑Seals

· Material Upgrade: PPDI polyurethane delivers three times the abrasion resistance of conventional TDI/MDI polyurethane, with 50 % improvement in hydrolysis stability.

· Filler Modification: PTFE micropowder, MoS₂, or graphite reduces coefficient of friction to 0.1–0.2.

· Lip Geometry: Asymmetric lip profiles, spiral return grooves, or stepped cutting edges generate a hydrodynamic oil film and prevent dry running.

· Surface Treatment: Nano‑ceramic or PTFE coating increases surface hardness to HV 800+.

2. Temperature Resistance by Grade

Grade Range Material Typical Application

Medium‑temp –30 °C to +130 °C HNBR / hi‑PU Mobile hydraulics

High‑temp –20 °C to +200 °C FKM All mineral/synthetic oils

Ultra‑high‑temp –10 °C to +260 °C FFKM Aerospace, semiconductor

3. How to Choose: Hole, Shaft, or Universal?

Type Example Code Applicable Std Feature Hot Search Region

Hole (piston) UHPR ISO 5597 Outer lip seals; I.D. seats on groove bottom South Africa (size matching)

Shaft (rod) UHSR DIN 3771 Inner lip seals; O.D. backed by anti‑extrusion ring France (DIN)

Universal UUNI GB/T 3452.1 Bidirectional; fits hole or shaft Taiwan, Japan

Custom‑Size Capability:

The search term “Custom size ISO 5597 U‑seal” (220 monthly searches) confirms strong demand for non‑standard dimensions. We offer any cross‑section from 2 mm to 15 mm, with any inner/outer diameter combination. Lead time: 2 weeks.

Conclusion:

When your equipment must operate continuously in abrasive dust or endure thermal cycling, do not let the seal be the weakest link. Our wear‑ and temperature‑optimized U‑seals are engineered for extremes.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY