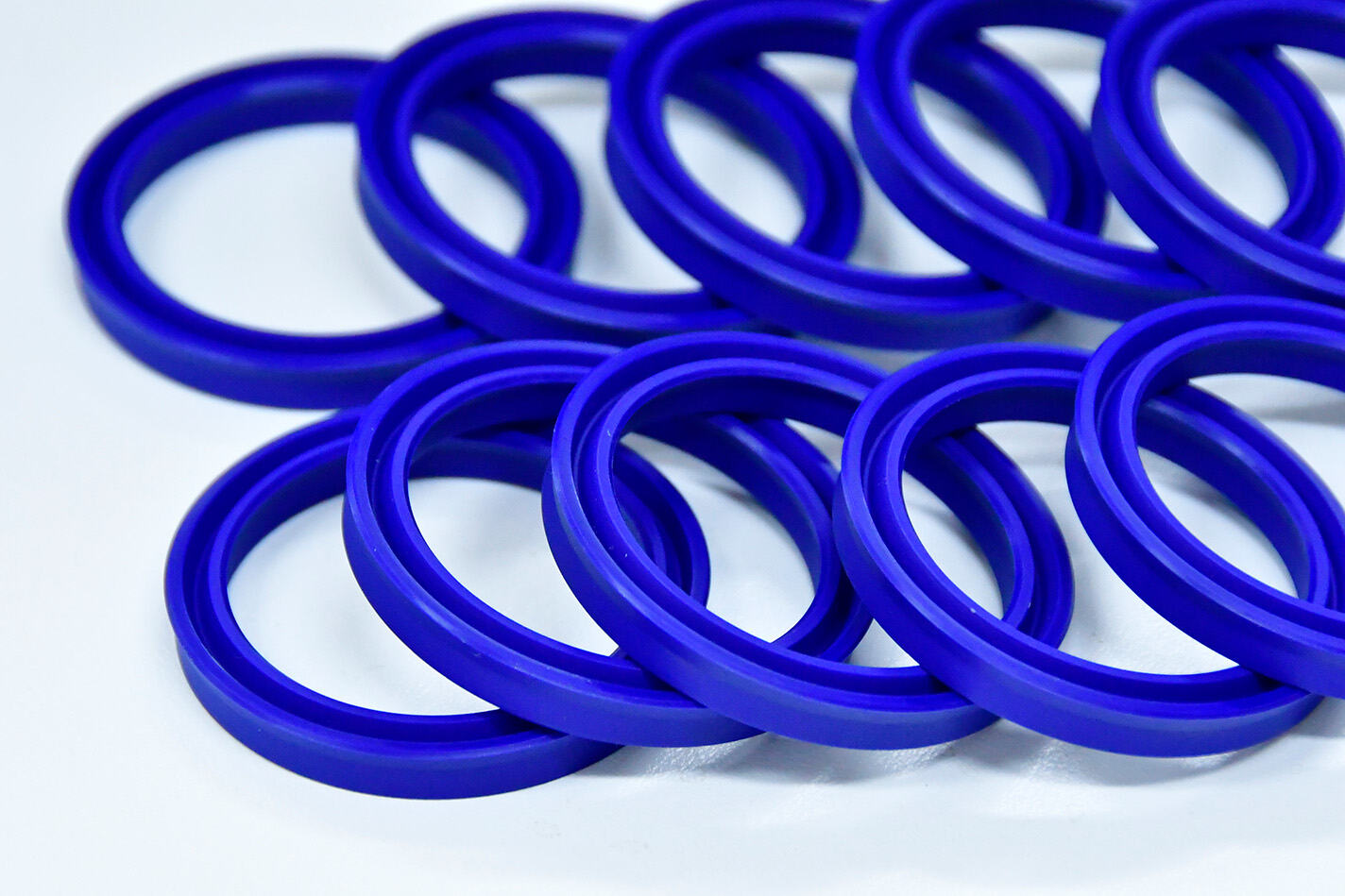

“Cost‑effective” does not mean “cheap.” It means achieving the lowest total life‑cycle cost while meeting all functional requirements. For high‑volume, standardized hydraulic and pneumatic systems, the correct U‑seal selection can reduce unplanned downtime by 70 % and cut procurement expenditure by 30 %. This article explains why our U‑seals are the “economy all‑rounder” for general automation.

1. Cost Components of a Hydraulic U‑Seal

· Purchase Price: NBR is the lowest‑cost material; FKM is the highest; PU sits in the middle.

· Installation Cost: Molded standard sizes (e.g., ISO 5597) require no hand‑fitting, saving assembly labor.

· Failure Cost: Oil replenishment, filter replacements, and unscheduled stops caused by premature leakage.

· Inventory Cost: One groove accepting multiple materials dramatically reduces SKU count.

Data Insight:

The search phrase “Hydraulic U‑seal size matching standard” (230.4K monthly searches, South Africa) indicates global concern about correct dimensional selection. Specifying U‑seals that conform to ISO, DIN, GB, or JIS directly reduces selection errors.

2. Special Requirements of Pneumatic Systems

Pneumatic systems are characterized by poor lubrication, high cycle rates, and low pressure (typically ≤1.6 MPa).

· Material: Low‑temperature NBR (–40 °C) or PU to avoid brittle fracture.

· Friction Control: PTFE‑coated U‑seals; break‑out pressure <0.05 MPa.

· Cross‑Section Design: Thin lip, reduced interference to prevent stick‑slip.

3. How We Deliver Extreme Cost‑Effectiveness

1. Formulation Optimization: Highly filled carbon‑black NBR achieves wear resistance approaching that of PU at 60 % of the material cost.

2. Mould Sharing: All popular cross‑sections (3.0, 4.0, 5.0, 6.3, 8.1 mm) are produced using common mould frames, enabling rapid changeover.

3. Regional Stock Positioning: Safety stock is prepositioned for hot‑search countries (India, USA, South Africa). Express airfreight upgrades are billed at cost only.

Customer Case:

A manufacturer of agricultural hydraulic cylinders previously purchased imported FKM U‑seals, spending USD 1.2 million annually. We recommended a switch to PU with cross‑section adjusted to DIN 3771. Performance fully satisfied the –20 °C to +70 °C duty cycle, cost dropped to USD 480,000 per year—an annual saving of USD 720,000.

Conclusion:

No over‑engineering, no cheapening. True affordability comes from precise application matching and efficient production logistics.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY