1.NBR 70 Shore A O-Ring Performance Specifications

Nitrile(NBR)o-rings are the most widely used o-ring material because of low cost,good mechanical performance with resistance to water,oils and fuels.Nitrile provides excellent resistance to petroleum products,and its ability to be compounded for service over a temperature range of-35C to +120℃(-30°F to +250°F).Buna-N nitrile exhibits excellent tensile strength and abrasion resistance properties.With a standard hardness of 70 Shore A,this material offers high tensile strength and superior abrasion resistance.Nitrile materials also exhibit excellent compression set,tear and abrasion resistance.The as 568 116 o ring is designed to maintain a leak-tight seal within a temperature range of-40℃ to +120℃.Its physical properties make it resilient against the mechanical wear typical of dynamic sealing applications in heavy-duty hydraulic equipment.

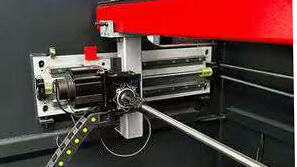

2.Punching Machine,Bender,and Shearing Machine Working Conditions

Heavy-duty metal fabrication tools like punching machines,benders,and shearing machines rely on high-force hydraulic actuators to deform or cut metal sheets.In hydraulic press brakes or bending machines,the system is subjected to rapid cycling and extreme mechanical vibration.These conditions require robust mechanical seals that can handle sudden pressure fluctuations without failing.Nitrile O-rings are widely specified in hydraulic cylinders,manifolds,and hose fittings to prevent fluid loss and maintain consistent pressure.The AS-116 size is commonly used in hydraulic hose fittings and manifold ports in these machines.Without high-quality Buna-N nitrile components,the hydraulic system would suffer from fluid leaks,leading to decreased force,reduced precision,and potential downtime in metal forming operations.

3.AS-116 Size Chart &Dimensions for Heavy Machinery

The AS-116 is a critical mid-sized O-ring used globally in high-pressure hydraulic connections and heavy machinery.

|

AS568 Dash No. |

Inside Diameter (ID) |

Cross Section (CS) |

Material |

Hardness |

|

AS-115 |

0.674 in (17.12 mm) |

0.103 in (2.62 mm) |

NBR (Buna-N) |

70 Shore A |

|

AS-116 |

0.737 in (18.72 mm) |

0.103 in (2.62 mm) |

NBR (Buna-N) |

70 Shore A |

|

AS-117 |

0.799 in (20.29 mm) |

0.103 in (2.62 mm) |

NBR (Buna-N) |

70 Shore A |

Conclusion

For the rigorous demands of bending,punching,and shearing operations,the as 5681160 ring provides a durable and reliable sealing interface.Its NBR 70 durometer material ensures excellent compatibility with petroleum-based hydraulic fluids and superior resistance to abrasion.When performing maintenance on high-force fabrication machinery, always ensure your seals meet the correct AS568 sizing to prevent costly leaks and downtime

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY