Underground mining is an unforgiving discipline where equipment operates in confined, dirty, wet, and mechanically stressful environments. Reliability is not merely an economic concern but a core component of safety. Three of the most critical machines—mine hoists, Load-Haul-Dump vehicles (LHDs), and drill jumbos—depend on hydraulic and mechanical systems where seal failure can lead to catastrophic results: a hoist brake failure, loss of steering on an LHD, or a hydraulic hose burst near a drill operator.

Mine Hoists:

These are the elevators for men, materials, and ore, moving massive loads at high speeds in vertical shafts. Their braking systems are typically hydraulic or hydro-pneumatic, operating under high pressure and requiring absolute reliability. Seals in the brake calipers and accumulators are subjected to:

· High Static and Dynamic Pressure.

· Potential for contamination from airborne shaft dust.

· Safety-critical functionality.

Hydrogenated Nitrile (HNBR) is the preferred material for these seals. It provides the excellent oil resistance of standard NBR but with dramatically improved:

· Heat Resistance (up to 150°C continuous), crucial for brakes.

· Mechanical Strength and Abrasion Resistance.

· Resistance to Ozone and Aging.

These properties ensure the seal maintains its integrity and elasticity over long periods, a non-negotiable requirement for a safety system.

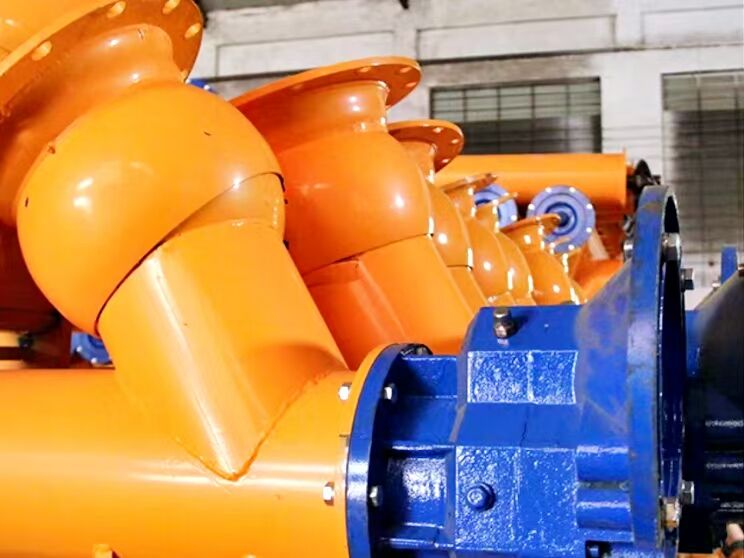

LHDs (Load-Haul-Dump):

These articulated, tramming vehicles are the workhorses of production mining. Their numerous hydraulic cylinders (for steering, lift arm, bucket tilt) undergo constant, high-force dynamic cycling. The primary challenge for cylinder seals is extrusion and abrasion.

· Polyurethane (PU) is the dominant material for piston and rod seals in LHD cylinders. Its unparalleled abrasion resistance and high modulus (hardness) prevent the seal from deforming and extruding into the tight clearance between the piston and cylinder bore under pressures that can exceed 300 bar.

· HNBR is often used for secondary seals, wipers (scrapers), and static seals within the cylinder assembly. It provides excellent backup sealing and resists the hot hydraulic oil.

Drill Jumbos:

These machines use hydraulic rock drills to create blast holes. The drill feed cylinder and the hammer/rotation mechanism are subjected to intense, high-frequency pressure pulses and vibration that can quickly destroy lesser seals.

· A combination of PU and HNBR is standard. PU handles the high-pressure sealing in the feed cylinders, while HNBR is used in the intricate seals of the drill head, where it resists the abrasive rock dust and high-temperature oil.

OEM Collaboration and Predictive Maintenance:

Suppliers like Atlas Copco, Sandvik, and Caterpillar design their equipment with specific seal profiles and material recommendations. Using non-OEM or incorrect material seals can void warranties and compromise performance.

In deep, hot mines in Western Australia and the USA (Nevada), ambient rock temperatures can exceed 50°C, further stressing hydraulic systems. Here, maintenance strategies are advanced:

1. Oil Analysis: Regular sampling of hydraulic fluid tracks viscosity, particle count, and most importantly, the presence of silicon (from abrasive dust ingress, indicating seal/breather failure) or copper/iron (from wear).

2. Condition-Based Replacement: Rather than fixed-hour intervals, seals in critical systems are replaced based on oil analysis results and teardown inspections during planned rebuilds.

3. Seal Upgrade Programs: Mines often work with seal manufacturers to develop custom compounds—for example, a hybrid PU with improved hydrolysis resistance for wet conditions or a specially fortified HNBR for higher-temperature drills.

The economics are clear: an unplanned LHD or jumbo breakdown in a remote underground stope can cost tens of thousands of dollars per hour in lost production. Investing in the correct, high-performance HNBR and PU seals, and implementing a science-backed maintenance program, is one of the most effective ways to ensure equipment availability and safeguard the underground workforce.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY