The mineral processing plant is a symphony of size reduction, classification, and separation. Key equipment like ball mills, vibrating screens, and magnetic separators each play a specific role, and each presents a distinct set of challenges for the seals that keep them running. The goal is always the same: prevent lubricant loss, exclude process slurry and contaminants, and maximize equipment uptime

Ball Mills / Grinding Mills:

These rotating drums, filled with grinding media, reduce ore to a fine slurry. Sealing points include the trunnion bearings (supporting the mill), feed chutes, and discharge grates.

· Environment: Abrasive slurry splash, water, and occasionally process chemicals (flotation reagents, pH modifiers). Heat is generated from the grinding action.

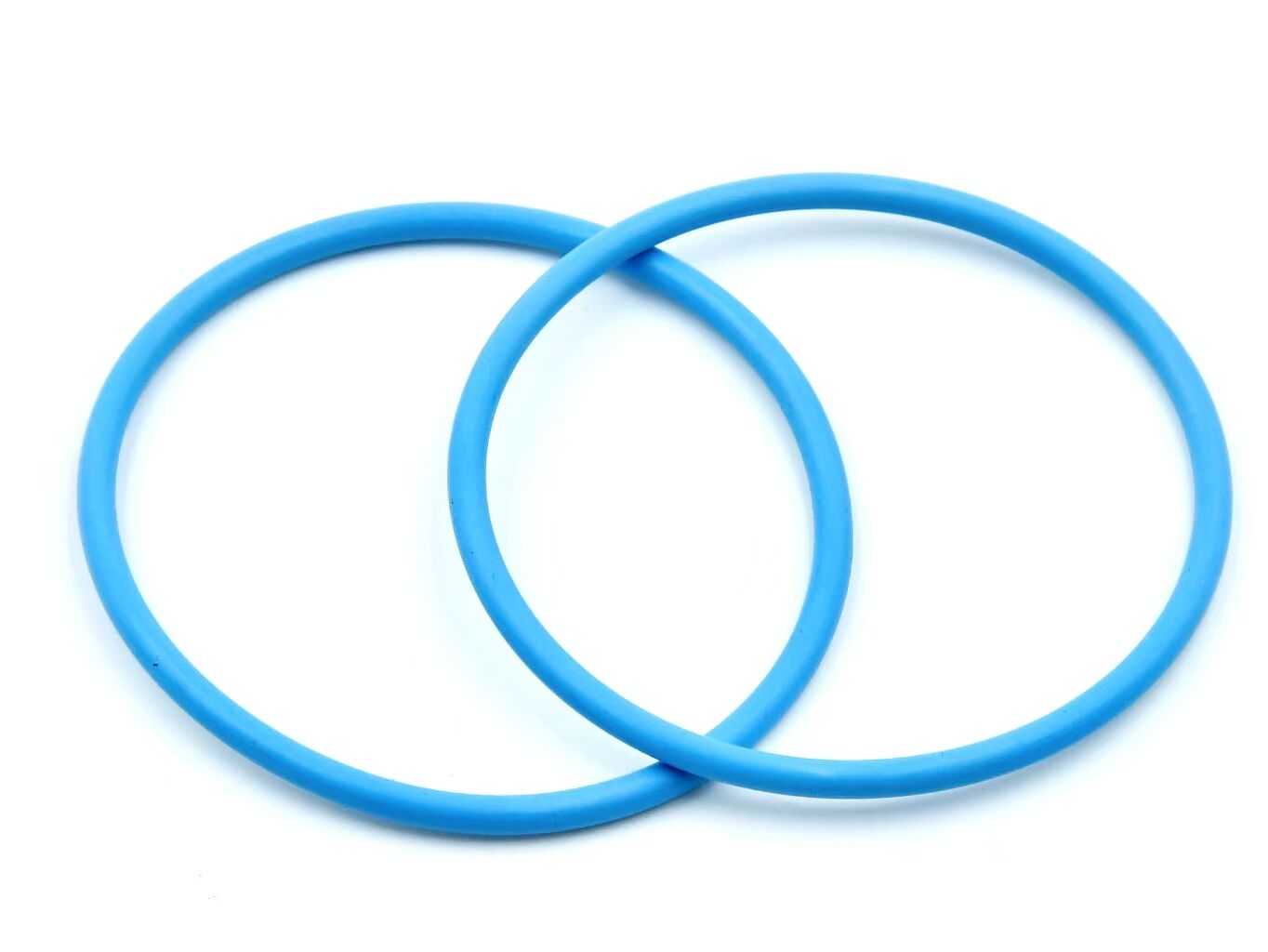

· Trunnion Bearing Seals: These are large-diameter seals protecting extremely expensive spherical roller bearings. They must handle possible misalignment and slurry splash. Multi-lip labyrinth seals with FKM lips are increasingly common. FKM is chosen for its:

· Excellent resistance to abrasion and cutting.

· Superior chemical resistance to any reagents that may wash back.

· Ability to withstand the elevated temperature at the bearing housing.

· Feed/Discharge Seals: For static gaskets on feed heads and discharge housings, NBR is often sufficient and cost-effective, unless the slurry is highly acidic, warranting FKM or EPDM.

Vibrating Screens:

Used for sizing, these machines impart high-frequency, linear or circular motion to screen decks. Bearings on the vibrator shaft are the lifeblood of the machine.

· Environment: Constant, high-G vibration, dust from the screened material, and possible moisture.

· Bearing Seals: The primary failure mode is fatigue cracking of the seal lip due to constant flexing. NBR compounds with excellent dynamic fatigue resistance and good tear strength are specified. The seal design often includes a spring-energized lip to maintain constant contact force despite vibration. Grease purging systems are vital to keep the seal contact zone clean. In screens processing corrosive materials, CR seals may be used for their better environmental resistance.

Magnetic Separators:

These include wet drum separators (for heavy media recovery) and cross-belt/dry drum separators.

· Wet Drum Separators: The rotating drum is partially submerged in slurry. Shaft seals prevent slurry from entering the bearing housing. This is a classic battle between abrasion and corrosion. FKM is frequently the best choice as it resists both the abrasive particles and any corrosive elements in the slurry (e.g., seawater in coastal plants, acidic process water).

· Dry Separators & Cross-Belt Separators: Seals are mainly for bearing protection from dust. NBR is standard, but if the dust is magnetic and fine (likely to adhere and penetrate), a more abrasion-resistant compound or a dual-lip design is used.

Global Maintenance Strategies for Optimization:

Progressive plants in South Korea (processing rare earths), India (iron ore and coal), and the USA (copper and gold) have moved beyond simple replacement to strategic seal management:

1. Standardized Bills of Materials (BOMs): Creating a plant-wide seal BOM for each equipment type (e.g., "Ball Mill Trunnion Seal Kit - FKM") reduces inventory errors and ensures the correct material is always used.

2. Failure Root Cause Analysis (RCA): When a seal fails prematurely, it is dissected. Is it cracked from heat? Worn from abrasion? Swollen from chemical attack? The answer dictates whether a material upgrade (NBR to FKM), a design change, or an operating procedure adjustment is needed.

3. Supplier Partnership for Custom Solutions: For example, a South Korean plant dealing with highly abrasive and slightly acidic tailings worked with a seal manufacturer to develop a PTFE-coated FKM seal for their wet drum separators, combining FKM's elasticity with PTFE's supreme lubricity and chemical resistance, resulting in a 400% increase in seal life.

4. Integration with Planned Maintenance: Seal replacement is scheduled during liner changes for ball mills or bearing inspection intervals for vibrating screens, ensuring no additional downtime is incurred.

This holistic view—matching the precise seal material (FKM for harsh chemical/abrasive/heat, NBR for general vibration/dust) to the specific duty, and managing it through a systematic plant reliability program—is what separates high-availability, low-cost-per-ton processing plants from those plagued by constant mechanical breakdowns.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY