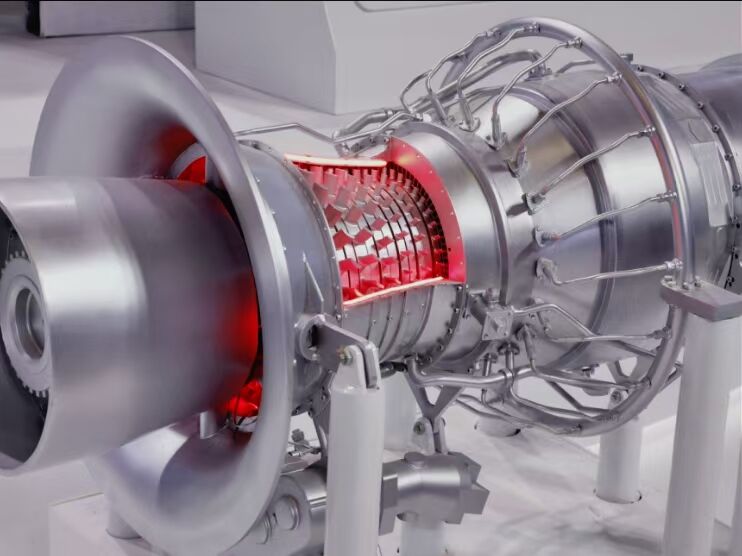

The relentless pursuit of efficiency in modern power generation has led to the widespread adoption of combined-cycle gas turbines (CCGT) and advanced-class steam turbines. These machines operate at breathtaking thermal efficiencies, but this comes at the cost of creating some of the most punishing environments for sealing components. Temperatures in gas turbine lube oil systems can routinely reach 150-180°C due to heat soak from the turbine casing, while steam turbine valve stems and gland sealing systems may be exposed to superheated steam at over 300°C. In these arenas, standard elastomers fail rapidly, leading to oil leaks, steam leaks, contamination, and forced outages with staggering financial penalties.

Fluorocarbon (FKM) elastomers are the first line of defense for high-temperature sealing in turbines. Their excellent balance of heat resistance (up to 230°C intermittent) and chemical resistance to synthetic ester-based turbine oils (e.g., ISO VG 32, 46) makes them the standard choice for most static and dynamic seals in the lubrication and control oil systems. Common applications include shaft seals on auxiliary pumps, O-rings in filter housings and valve actuators, and gaskets on sight glasses. The AS109 standard often specifies common FKM compounds for aerospace and industrial turbine applications, ensuring a baseline of performance. For additional mechanical strength in dynamic seals exposed to these hot oils, Hydrogenated Nitrile (HNBR) is sometimes used as an alternative, offering superior abrasion resistance and good oil compatibility up to about 150°C.

However, for the extreme heat zones, only Perfluoroelastomers (FFKM) such as Kalrez® or Chemraz® suffice. FFKM parts are not merely improved FKM; they are a different class of material with a fully fluorinated polymer structure. This gives them two transcendent properties:

1. Continuous Operating Temperatures above 300°C, allowing them to function in direct proximity to steam lines and hot gas paths.

2. Virtual Inertia to Chemicals, including aggressive turbine oils, heat transfer fluids, and process gases that would degrade FKM over time.

Their application is highly targeted due to cost (often 50-100 times that of FKM). Key locations include:

· Steam Turbine Main Stop & Control Valve Stem Seals: Directly exposed to high-pressure, high-temperature steam. A leak here represents a direct loss of cycle efficiency and a safety hazard.

· Gas Turbine Fuel Gas Valve Seals: Exposed to hot fuel gas and possible condensation of aggressive compounds.

· Seals on Sensing and Instrumentation Lines penetrating hot turbine casings.

OEMs like GE, Siemens, and Mitsubishi Power provide explicit material specifications for these critical locations. The selection logic is driven by a Failure Mode, Effects, and Criticality Analysis (FMECA). Engineers assign a risk priority number (RPN) to each sealing point based on the severity of failure, likelihood of occurrence, and detectability. For points with a high RPN, the superior performance of FFKM justifies its cost.

This principle is applied globally. In Bahrain, where CCGT plants provide base-load power in a high-ambient-temperature desert environment, cooling is less effective, pushing oil and surface temperatures higher. Specifying FFKM for critical valve stems is a proactive reliability investment. In the Philippines, geothermal and coal-fired plants with older steam turbines have successfully retrofitted FFKM seals to stop chronic steam leaks, improving plant efficiency and personnel safety. In the USA, stringent environmental regulations concerning volatile organic compound (VOC) emissions from leaks (LDAR programs) make the leak-free performance of FFKM in fugitive emission applications economically attractive. The total cost of ownership calculation must factor in not just the seal price, but the avoided cost of lost generation, repair labor, and environmental compliance.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV SR

SR SK

SK VI

VI HU

HU MT

MT TH

TH TR

TR FA

FA MS

MS GA

GA CY

CY IS

IS KA

KA UR

UR LA

LA TA

TA MY

MY