33-99No. Mufu E Rd. Gulou District, Nanjing, China [email protected] | [email protected]

Dynamic sealing is a crucial part of hydraulic cylinders. Currently, high-pressure heavy-duty hydraulic cylinders mostly use Glyd Rings and Stepseals. These were the core products of the Busak+Shamban company (referred to as Busak+Shamban). Many domestic enterprises now also produce these two types of seals.

In the 1990s, the former Shanghai Sanxin Hydraulic Company acted as an agent for Busak+Shamban. We were responsible for technical services and sales in East China. During this time, we compiled Chinese manuals and promotional materials. We also registered trademarks for their products and gave technical presentations.

We visited the company headquarters in Germany, as well as branches in the United States and Japan. We toured their laboratories and production workshops. In 1996, during a visit to the US branch, I met the engineers who originally developed the Glyd Ring and Stepseal. We discussed technical issues, and I learned a great deal.

Historically, most seals are named after their shape. For example, there are O-rings, Y-rings, and U-rings. However, the Glyd Ring and Stepseal are exceptions. This article provides a comprehensive overview of these seals.

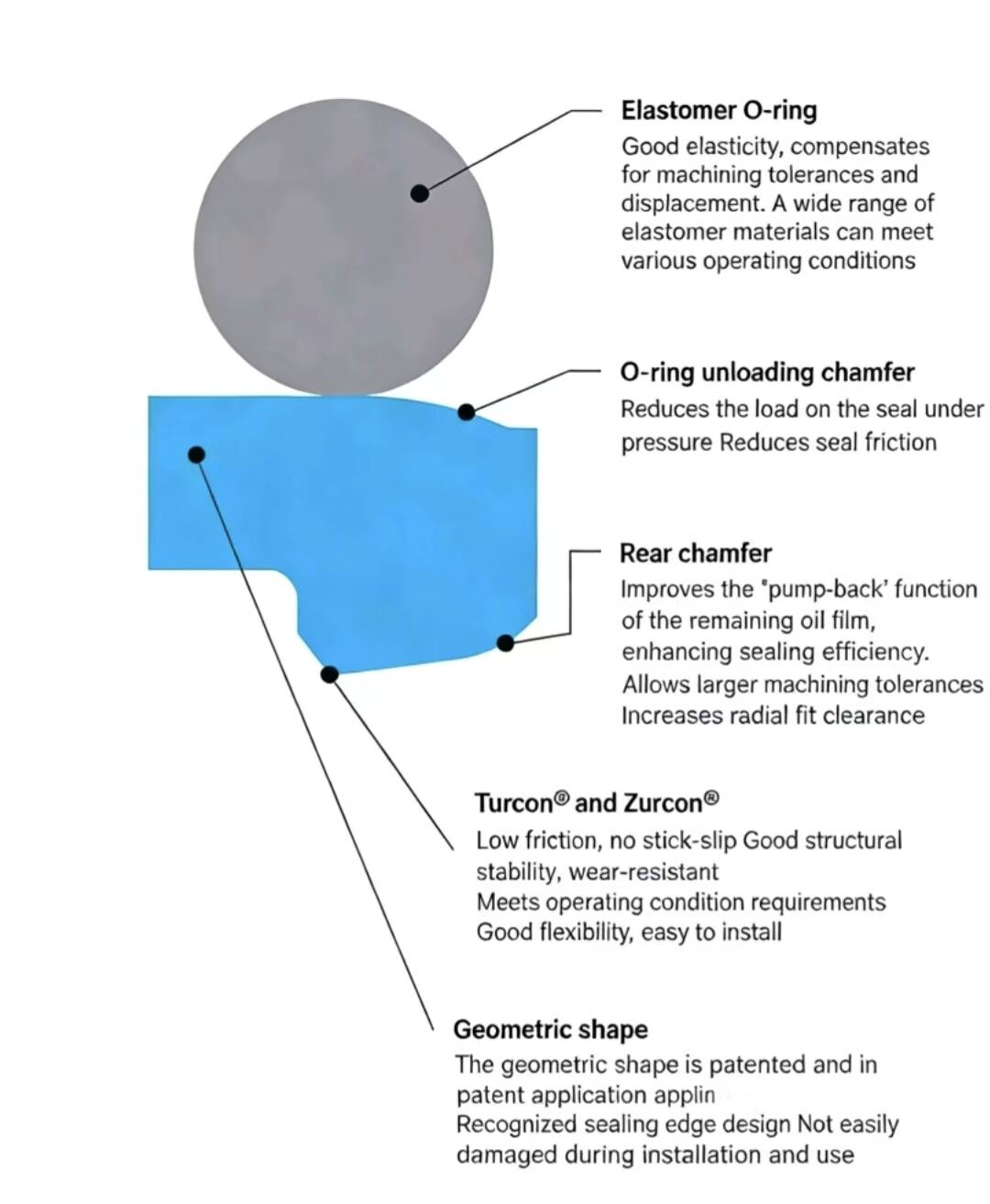

These two seals are made of an elastic body and a sealing ring. The elastic body uses a standard nitrile rubber O-ring. It can also use an X-ring or a rectangular ring. The sealing ring is made of filled fluoroplastic. Its commercial registered name is Turcon. It is machined from a sintered tubular blank.

The Glyd Ring went through continuous improvement from 1971 to 1992. It has evolved into its third generation. The Stepseal also improved over time. After the K-type Stepseal, the 2K-type was introduced in 2004.

Turcon is an excellent sealing material. Decades of use have proven its great sealing and wear resistance. It is based on PTFE (Polytetrafluoroethylene). It is filled with bronze, molybdenum disulfide, graphite, or carbon fiber. This makes it extremely wear-resistant. It stays rigid even in harsh conditions. It resists almost all chemicals. Its water absorption is less than 0.01%. It also has a low friction coefficient. The static and dynamic friction coefficients are very close. This prevents the "crawling" (stick-slip) phenomenon in hydraulic cylinders.

The seal combines the elastic O-ring with the Turcon sealing ring. The O-ring acts as a static seal. It also applies radial pressure to the sealing ring. This lets the sealing ring do its job effectively. The Turcon ring handles the dynamic sealing. This combination uses the best strengths of both parts.

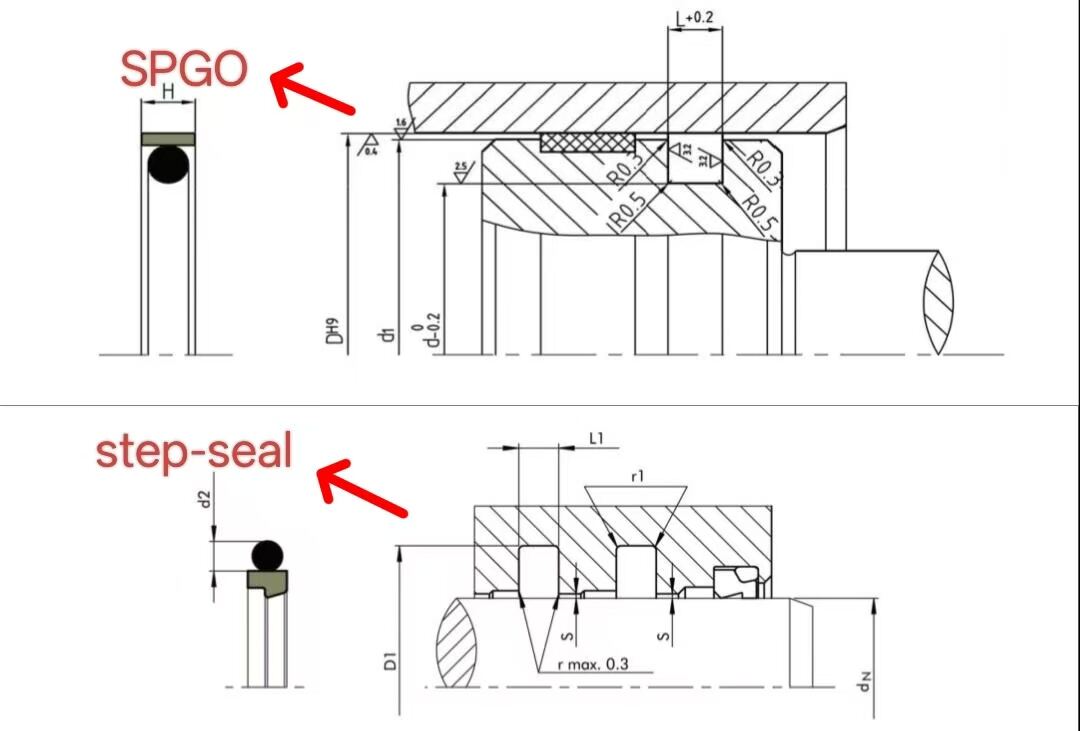

The Glyd Ring is used for sealing between the cylinder bore and the piston. It is a double-acting seal. The Stepseal is used for the piston rod. It is a single-acting seal. It is designed with a stepped shape to improve sealing. When two Stepseals are used in a series, they can achieve "zero leakage".

After these seals became mature and widely used, the Shamban company led the creation of German and International standards. In the early 90s, China's hydraulic and pneumatic standardization committee included these seals in their plans. Tianjin Engineering Machinery Research Institute drafted the standard. It was equivalent to the international standard.

The draft was approved in 1994. Implementation began in April 1995. The standard is named GB/T 15242.1-94. In English, it is titled Hydraulic fluid power-cylinder rod and piston seals for reciprocating application of co-axial seals -- Dimensions and tolerances.

"Glyd Ring" and "Stepseal" are registered commercial names. Sometimes, based on their use, they are simply called "piston combined seals" or "rod combined seals."

The English name "Glyd Ring" originally implies a sliding ring style. "Stepseal" implies a stepped style. It is said that the Chinese names (Ge-lai and Si-te) were translated phonetically by Hong Kong agents using Cantonese pronunciation. These became the common names we use today. They are quite different from the official product standard names.

In 1952, the American company W.S. Shamban began developing PTFE sealing materials for aerospace. They registered the name Turcon. They pioneered the patented Stepseal and Glyd Ring. Today, these names are known by every hydraulic cylinder designer.

In 1992, the German company Busak acquired W.S. Shamban. To keep both brands, they named the new company Busak+Shamban (B+S). It became a multinational supplier of high-quality seals and bearing devices.

B+S owns 11 material development labs and 17 design centers globally. They have 6 R&D centers and 80 factories. They are leaders in aerospace, construction machinery, metallurgy, and shipping industries.

Busak+Shamban has cooperated closely with Chinese customers for years. After China joined the WTO, they increased investment. Since 2000, they have opened offices in Wuhan, Shanghai, Dalian, Guangzhou, Xi'an, and Chengdu. They provide advanced sealing solutions across China.

In 2003, Busak+Shamban became part of Trelleborg AB, a listed company in Sweden. In April 2004, the company was officially renamed Trelleborg Sealing Solutions.

Most companies in China's hydraulic and pneumatic industry are small or medium-sized. Many are family-owned. They often lack capital, technical strength, and modern management. These companies fight for the low-end market. Their products are too similar. When the market is slow, they fight price wars. Cheaper products mean lower profits. This makes it hard to enter the high-end market.

Sha Baosen, Chairman of the Association, believes the only way out is reorganization. Whether through unions or mergers, restructuring is necessary. Fluid power products (hydraulics, pneumatics, seals) are basic components. They require large scale and wide variety. A single small company cannot succeed alone.

Industry giants like Bosch Rexroth, Parker, Eaton, and Moog prove this. They are large groups with many specialized factories. This industry is capital and technology-intensive. You need scale to be profitable. Therefore, mergers and reorganization are inevitable.

Since 2009, demand in the industry has risen. The Ministry of Industry and Information Technology created a plan to fix basic components. The main issues are a lack of innovation and low R&D investment. The product structure is unreasonable.

The country needs to speed up the development of basic industries. We must solve the problem of the equipment industry being "big but not strong." We must stop relying on foreign countries for key components. The industry must implement the "Equipment Manufacturing Adjustment and Revitalization Plan." We need to solve the "choke point" of relying on imported high-end products. With new government opinions on mergers issued in 2010, the industry may see new development opportunities.