33-99No. Mufu E Rd. Gulou District, Nanjing, China [email protected] | [email protected]

Nitrile o-rings and seals are the most commonly used o-rings and seals on the market. The popularity of the material is due in large part to its excellent mechanical properties. Nitrile is an elastomeric synthetic rubber compound, a copolymer of acrylonitrile and butadiene, from which it derives its other common names—nitrile butadiene rubber or NBR, acrylonitrile-butadiene rubber, or simply, Buna-N.

Nitrile offers excellent tensile strength, abrasion resistance, tear resistance, and compression resistance. It combines resistance with a low compression set and high abrasion resistance to make it the seal industry’s most widely used economical elastomer. This also makes it a cost-effective alternative to fluoroelastomers. Nitrile holds high fuel and oil resistant properties. In addition to its excellent fuel and oil resistant properties, nitrile rubber displays excellent resistance to moisture and water, various alcohols, silicone greases, and hydraulic fluids. Other advantages are its good tear resistance and non-polar solvent resistance.

Optimal environments include petroleum oils and fuels, silicone oils and greases, propane, ethylene glycol, butane, vegetable and mineral oils and greases, dilute acids, and water and steam applications (below 212°F). Nitrile compounds are superior to most elastomers, offering superior strength and more resistance than any natural rubber to oils and acids. They perform well and are compatible with petroleum-based oils and fuels, vegetable oils, silicone oils and greases, aliphatic hydrocarbons, ethylene glycol, dilute acids, and water to temperatures up to 212ºF (100ºC).

Because nitrile can be compounded for various applications, it offers stability for service over a temperature range of approximately -35°F to 250°F (-37°C to 120°C), providing excellent compression set, tear, and abrasion resistance at those working temperatures. Normal recommended temperature range; extended temperature range for short term only. Heat Resistance: Up to 212°F (100°C) with shorter life @ 250°F (121°C). Cold Flexibility: Depending on individual compound, between -30°F and -70°F (-34°C and -57°C).

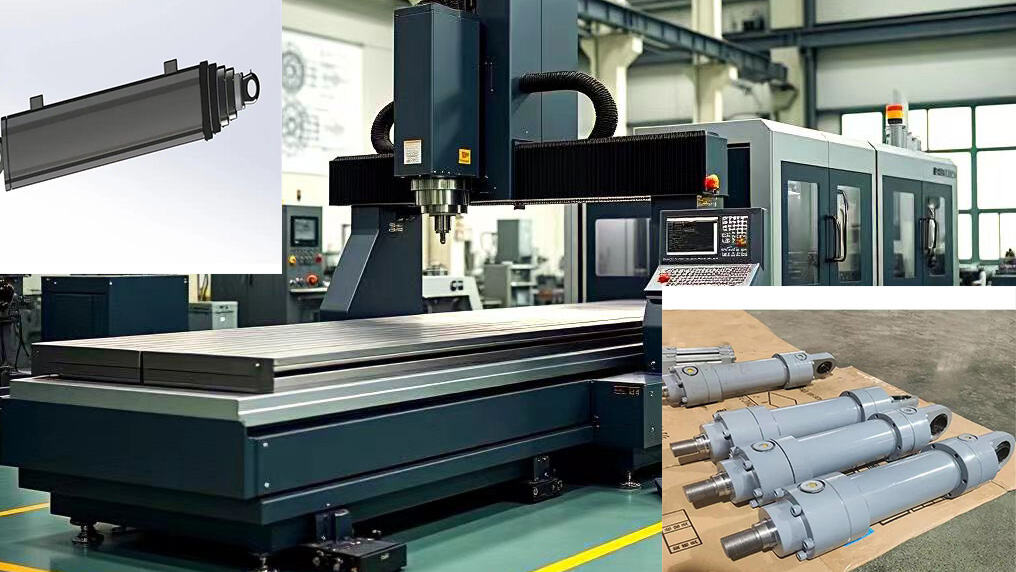

With such wide working temperatures, nitrile o-rings and seals are used extensively throughout the automotive and aeronautical industry, and in the manufacture of other products like fuel and oil handling hoses, grommets, and self-sealing fuel tanks. It is such stability at low temperatures that make nitrile ideal for many aeronautical applications. Given their exceptional properties, Buna o-rings find application across various industries, including automotive, aerospace, oil and gas, agriculture, and food processing.

Though nitrile is a well-suited material with many general purpose applications, it does have its limitations. It is incompatible with different types of fluids, including automotive brake fluid, ketones, phosphate ester hydraulic fluids, or nitro and halogenated hydrocarbons. Low resistance to ozone, sunlight, and weathering. Incompatible with benzene, toluene, xylene, halogen derivatives (carbon tetrachloride, trichloroethylene), ketones (MEK, acetone), phosphate ester hydraulic fluids (Skydrol, Pydraul), strong acids, and glycol. It also suffers from poor ozone, sunlight, and weather resistance, flame resistance, and cannot be used in high heat applications