33-99No. Mufu E Rd. Gulou District, Nanjing, China [email protected] | [email protected]

Nitrile Rubber (NBR):

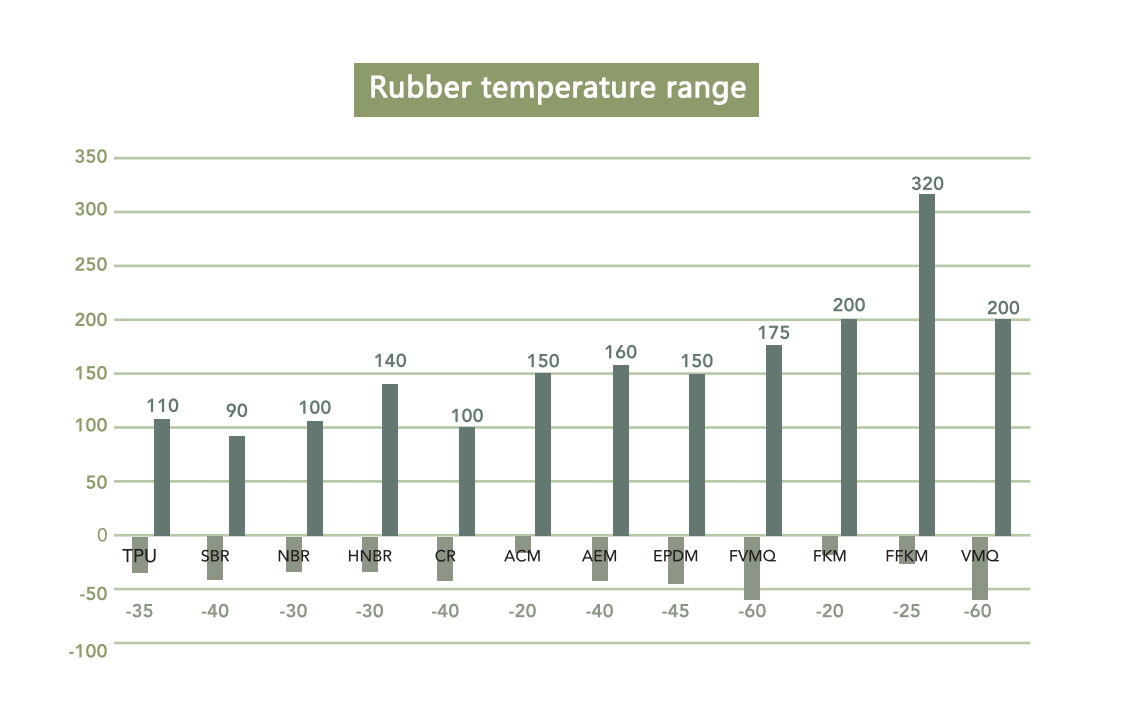

The performance primarily depends on the ACN content, which ranges from 18% to 50%. Generally speaking, they exhibit good mechanical properties and can be used within an operating temperature range of -30℃ to +100℃ (reaching up to +120℃ for short periods).

The confirmed nitrile rubber formula can be used at temperatures as low as -60℃. It is primarily used for mineral oil and lubricating grease.

Viton (FKM):

Based on differences in structure and fluorine content, there may be variations in chemical resistance and cold flexibility. It is renowned for its non-flammability, low air permeability, and excellent ozone resistance, weather resistance, and light resistance. The operating temperature range for application is -20°C to +200°C (reaching up to +230°C for short periods).

The special formula can be used at temperatures as low as -35℃, and is also frequently used at high temperatures in conjunction with mineral oil and lubricating grease.

Ethylene Propylene Diene Monomer (EPDM):

They exhibit excellent heat resistance, ozone resistance, and aging resistance. Furthermore, they possess high levels of elasticity, superior low-temperature performance, and good insulation properties. The operating temperature range for application is from -45℃ to +150℃ (reaching up to +175℃ for short periods). For vulcanized and cured types, the range can be reduced to -45℃ to +120℃ (reaching up to +150℃ for short periods)

It is commonly used in applications involving brake fluid (based on ethylene glycol) and hot water.

Hydrogenated Nitrile Rubber (HNBR):

It is produced through the selective argonation of nitrile groups. Its performance depends on the ACN content, ranging from 18% to 50%, as well as the saturation level. It exhibits good mechanical properties. When in contact with mineral oil and lubricating grease, the applicable operating temperature ranges from -30℃ to +140℃ (up to +160℃ for short periods). Special formulations can be used at temperatures as low as -40℃.

Silicone (SIL):

It possesses excellent heat resistance, cold flexibility, and dielectric properties, particularly outstanding oxygen resistance and ozone resistance. Depending on the material, the operating temperature range is between -60℃ and +200℃ (even up to +230℃, it can be used for short periods of time).

It is commonly used in the medical and food industries.

Chloroprene Rubber (CR):

Generally speaking, they exhibit relatively good ozone resistance, weather resistance, chemical resistance, and aging resistance. In addition, they possess good non-flammability, excellent mechanical properties, and cold flexibility. The operating temperature range is between -40℃ and +100℃ (up to +120℃ for short periods). Special types can be used at temperatures as low as -55℃.

It can be used for sealing applications, such as refrigerant, outdoor applications, and the adhesive industry.

Acrylate Copolymer (ACM):

It exhibits excellent resistance to ozone, weathering, and hot air, despite only demonstrating moderate physical strength, low elasticity, and relatively limited low-temperature capabilities. The operating temperature range is -20℃ to +150℃ (up to +175℃ for short periods). Special types can be used at temperatures as low as -35℃.

Primarily used in automotive applications, these applications require special resistance to lubricants containing many additives (including sulfur) at high temperatures.

Perfluoroelastomer (FFKM):

It exhibits extensive chemical resistance similar to PTFE and good heat resistance. Depending on the material, the operating temperature range is between -25℃ and +240℃, and special formulations can be used at temperatures up to +325℃.

The application is primarily seen in the chemical and semiconductor industries, as well as in all applications involving corrosive environments or high temperatures.

Note:

When selecting O-ring materials, chemical compatibility should be considered. Our company has conducted immersion tests under laboratory conditions and can provide recommendations for material selection.

Relatively short-term laboratory tests may not fully align with all the additives and impurities that may exist in long-term applications. Therefore, before selecting materials, it is essential to ensure that all aspects of the application, such as high temperature, compression deformation, hardness, wear resistance, and thermal expansion, are carefully considered. It is recommended that users conduct their own tests to confirm whether the selected materials are suitable for each application.